You will receive a plan of action and a list of required documents for preparation for construction or renovation shortly!

We bring your dreams to life in reliable structures!

Flexible pricing

for clients

Staged payments

no extra charges or interest

Work guarantees

specified in the contract

Free visits

for measurements and estimates

Wide range

of services for clients

Construction of Houses in Barcelona

Steel Frame House Project - Ready for Construction

Steel Frame House Project (light steel frame constructions) — is a modern solution for quick, economical, and durable construction. Steel frame constructions consist of a steel framework assembled from lightweight galvanized profiles. This construction method allows for the design of a home with high precision, creating an energy-efficient and warm residence, while also significantly reducing construction time.

Designing steel frame houses includes calculating all structural elements, selecting insulation and finishing materials, as well as planning spaces to meet client needs. Thanks to frame technology, such projects are suitable for various building types — from private homes and cottages to commercial properties.

Leoviten Company offers a ready-to-build steel frame house project, which has already been approved and is available for download. You can review the project, assess its benefits, and view all details.

View Steel Frame House Project

Photos of the Completed Steel Frame House — Exterior

Below are photos showcasing the exterior of the house built using steel frame technology (light steel frame constructions). These images display the advantages of steel frame technology in the exterior: modern lines, a variety of finishing materials, and structural durability.

The exterior of the steel frame house can be designed in any style — from classic to ultra-modern. With the high precision of frame elements, perfect proportions and clean lines on the facade can be achieved. Steel frames allow for the use of various finishing materials, such as facade panels, wood, brick, or decorative plaster.

Interior Finishing of a House Built with Light-Gauge Steel Framing — Interior

The interior of a house built with light-gauge steel framing is comparable in quality and finishing options to houses constructed using traditional methods. Thanks to the sturdy and even steel profile foundation, walls and ceilings are perfectly suited for all types of interior finishes, including drywall, wallpaper, decorative plaster, and paint.

Light-gauge steel framing technology allows for diverse design solutions: spacious rooms with high ceilings, modern kitchens, stylish living rooms, and cozy bedrooms. Interior walls can be easily adapted for the installation of utilities, simplifying the setup of electrical wiring, heating, and ventilation systems.

In the photos, you can see examples of interiors created in our house project built with light-gauge steel framing. The light structures, high-quality finishes, and functional layout provide a comfortable and modern living space.

Bathroom Photos — Interior

Photo Room — Interior

Photo Living Room — Interior

Photos of the Structure of a House with Light Steel Frame Construction – Walls

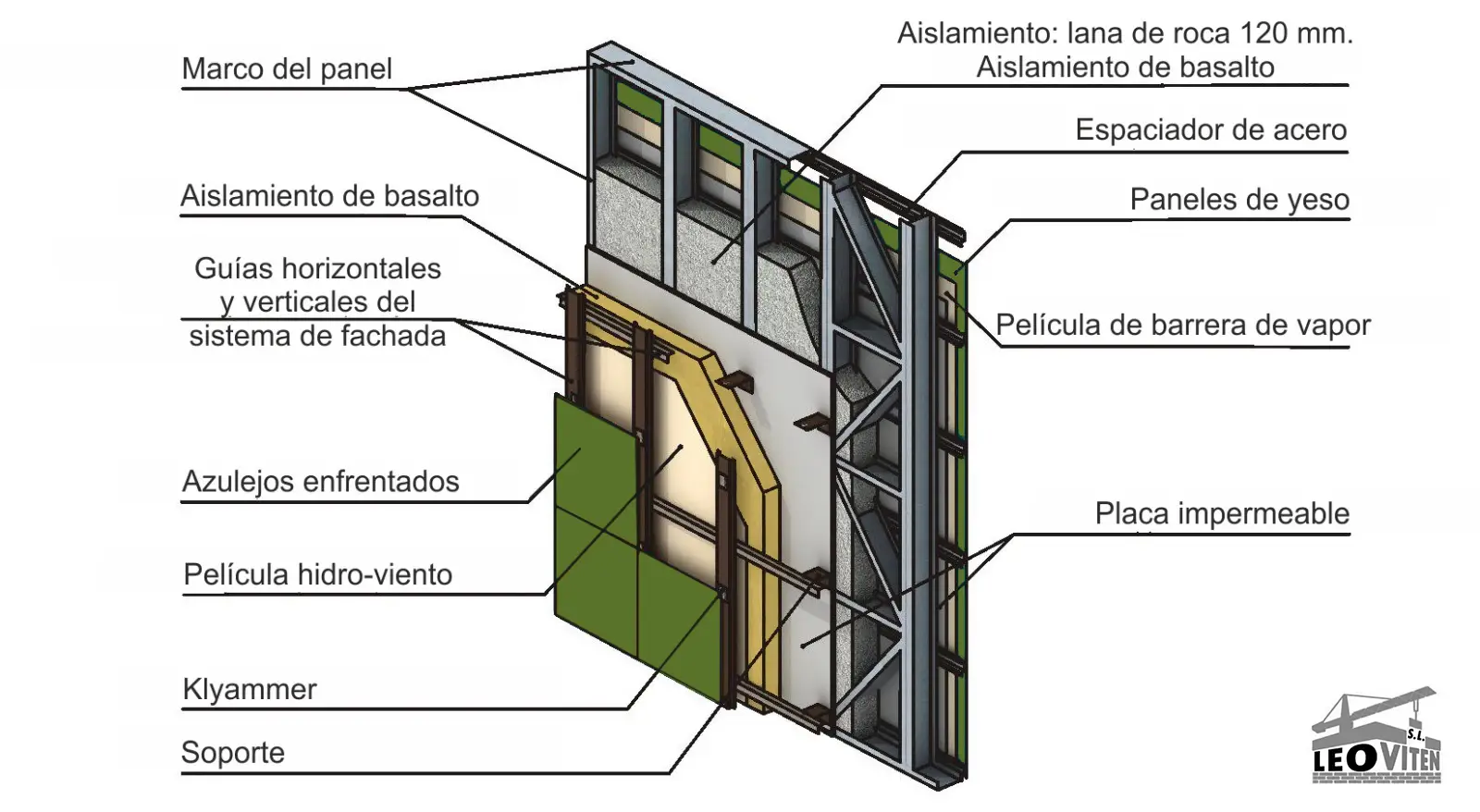

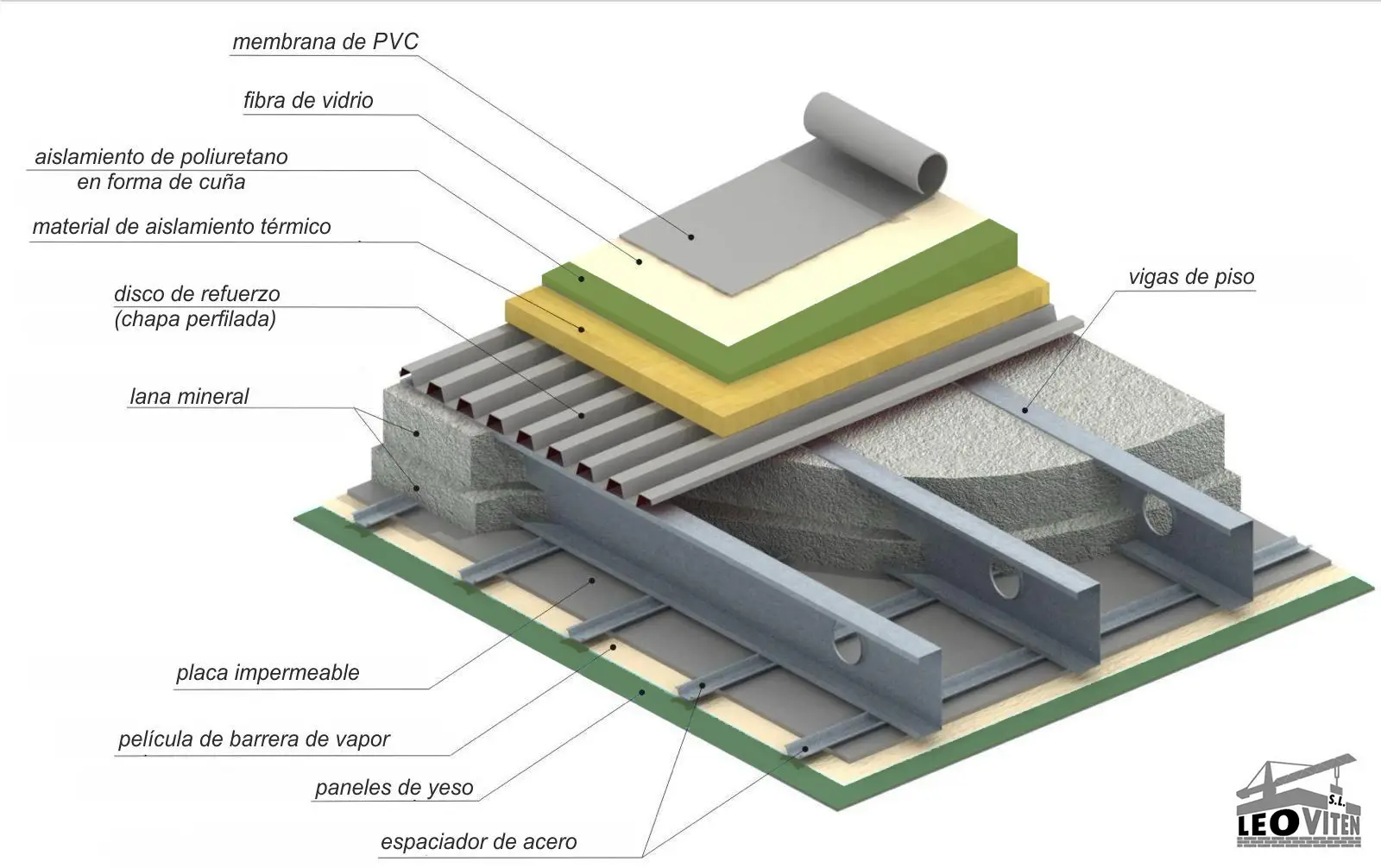

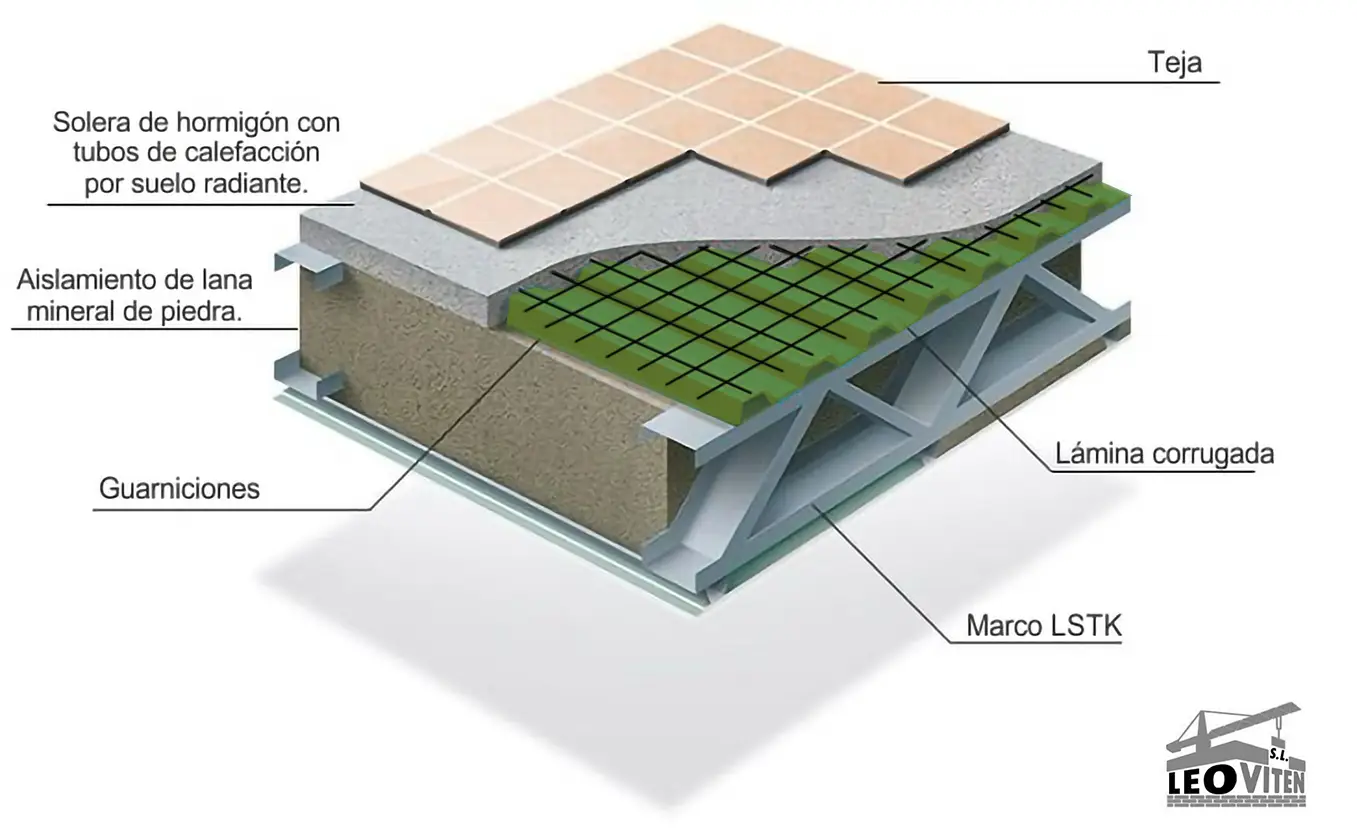

Walls of a house built using light steel frame construction technology consist of several layers, each serving a specific function. The foundation is a sturdy frame made of galvanized steel profiles, providing load-bearing capacity, durability, and structural stability. The steel frame is lightweight but capable of supporting significant loads.

The structure of a wall with light steel frame construction includes the following layers:

- Steel frame – composed of vertical and horizontal profiles that form the wall's foundation. The profiles are made of galvanized steel to prevent corrosion and extend the construction's lifespan.

- Thermal insulation – usually mineral wool or polystyrene, used to fill the space between the profiles. This helps retain heat in the house and improves the building's energy efficiency.

- Vapor barrier – a special membrane that protects the insulation from moisture and prevents the accumulation of condensation inside the walls. This is an essential element for maintaining a comfortable indoor climate and preserving the insulation's longevity.

- Windproof membrane – installed on the exterior to shield the walls from wind and moisture while maintaining breathability.

- Exterior cladding – the outer layer, which can be made of various materials such as facade panels, decorative plaster, brick, or siding. The exterior cladding provides the building with the desired style and protects the structure from weather conditions.

- Interior cladding – gypsum board or another material used for interior wall finishes, prepared for decorative treatments such as painting or wallpapering.

Using light steel frame construction allows for the creation of warm, sturdy, and energy-efficient walls, while also ensuring fast and cost-effective assembly. In the photos, you can see the structure of a light steel frame wall at different stages of construction – from the framework to insulation and exterior cladding.

Questions and Answers About Light Steel Frame Construction in Barcelona

Light steel frame construction (light, thin-walled steel structures) is a durable, energy-efficient, and fast material to build with. It is ideal for Barcelona's climate, offering high resistance to moisture and temperature fluctuations. Due to its lightweight nature, construction times are significantly reduced while maintaining excellent quality.

On average, building a house with light steel frame construction takes 3-6 months, depending on the size and complexity of the project. This time frame is significantly shorter compared to traditional materials, allowing you to enjoy your new home sooner.

Our team has extensive experience in light steel frame construction and understands all the nuances of the technology. We provide full project support, from design to the turnkey delivery of the house, ensuring high-quality work, adherence to deadlines, and transparent collaboration terms.

Do you have any questions? Write to us!

Thank you for reaching out!